EXCELLENT CREDIT RATING STRUCTURE

CREFOZERT CREDIT RATING CERTIFICATE FOR THE SECOND YEAR IN SUCCESSION

For the second year in a row, the independent credit agency Creditreform has confirmed our excellent credit rating structure. We are proud to receive this award in these challenging times.

We would like to thank our business partners who have placed their trust in us and our employees who have once again made this success possible.

Rendsburg 08/23/2023

MEMBER OF DEUTSCHE YACHTEN

SCHIFFSDIESELTECHNIK KIEL GMBH IS NOW A MEMBER OF THE ASSOCIATION OF GERMAN SHIP AND BOAT BUILDERS

Since July 2023 SDT is a member of the “German Boat and Shipbuilders Association” (DBSV) in the association we participate in the working group “German Yachts” together with other well-known partners from the industry.

If you are also interested in German yachts:

https://www.deutsche-yachten.de/en/

We are looking forward to your inquiry.

By mail:

info@sdt-kiel.de

IN THE COURSE OF THE INTERVIEW SERIES "FIVE QUESTIONS TO ..." OF THE MARITIME CLUSTER NORTHERN GERMANY, OUR TECHNICAL MANAGING DIRECTOR FIN-OLAV WITTSTOCK ANSWERED QUESTIONS ON CURRENT TOPICS OF THE MARITIME ECONOMY.

WILL WE SOON HAVE TO DELETE THE WORD "DIESEL" FROM OUR COMPANY NAME?

From 20-meter workboats to 200-meter yachts – wherever there are special requirements for the power supply on board, Rendsburg-based SDT – Schiffsdieseltechnik Kiel GmbH is there with individual concepts for auxiliary power units and emergency diesel. In this interview, Chief Technology Officer Fin-Olav Wittstock talks about the future of the diesel engine, innovative fuel concepts and the shortage of skilled workers.

The whole interview (in German) can be found on the page of the maritime cluster Northern Germany or directly via the following link:

Aktuelles ⚓ Maritimes Cluster Norddeutschland e.V. (maritimes-cluster.de)

If you would like to discuss the future of your onboard power supply with us, we look forward to hearing from you:

WITH US YOU WILL NOT ONLY GET THE RIGHT JOHN DEERE ENGINES FOR YOUR PURPOSES, OF COURSE, WE WILL ALSO PROVIDE YOU WITH THE BEST SERVICE IN CONNECTION WITH THE NECESSARY ORIGINAL SPARE PARTS FOR YOUR JOHN DEERE INDUSTRIAL OR MARINE ENGINE.

WHERE CAN I EASILY GET THE BEST SERVICE AND THE RIGHT SPARE PARTS FOR MY ENGINE?

You only need the right spare part?

No problem, you can also get this from us in the rules even within 24 hours!

Our service technicians are constantly trained by John Deere and kept up to date with the latest technology.

In conjunction with the original spare parts, we enable you to maintain the performance of your John Deere engine and extend its service life to the maximum.

In short: The best solution for your aggregate.

We are looking forward to your request.

info@sdt-kiel.de

WHY YOU CAN TRUST SDT TO LEAD YOUR PROJECTS?

CREDITREFORM AWARDS US THE CREFOZERT CREDITWORTHINESS CERTIFICATE

The independent credit agency Creditreform has checked our company for creditworthiness and security and confirmed our excellent credit rating structure.

This seal, which only a few receive, stands for reliable business relationships and the highest solvency.

We are very proud of this positive assessment of the current situation and future prospects of our company.

Both the audited balance sheets and the personal interviews with the management showed that our company has met the high certification criteria.

Our customers and suppliers are very important to us. For this reason, we have taken the path of trustworthy certification. A solid foundation creates reliability.

Such an award is based on the joint high commitment of all employees of our company.

Therefore SDT stands especially also for job security on a high level and offers a high stability to all employees, but also to new applicants.

Let’s talk about your next project:

10.09.2021 WE HAVE RECEIVED THE GRANT NOTIFICATION FOR THE R&D PROJECT "DEVELOPMENT OF A COMPACT GENE SET WITH CO2-NEUTRAL FUEL"!

APPLICATION APPROVED: GENERATOR WITH CO2-NEUTRAL FUEL

By February 2023, we will develop a generator set with all the necessary peripherals for power generation with CO2-neutral fuel.

The modular base frame of the genset will allow the storage of a methanol combustion engine or a methanol/hydrogen fuel cell. Due to the planned use of methanol or hydrogen, the genset will be encapsulated from the eventual engine room with a gas-tight acoustic enclosure.

This should simplify the integration of the gene set into the respective engine room and fulfill the necessary requirements with regard to gas safety. As with the other R&D projects in the network, this innovation aims to enable installation in smaller vessels up to 60 meters. We are supported in this by ABEKING & RASMUSSEN Schiffs- und Yachtwerft SE and Rolls Royce Power Systems GmbH.

The development of this exciting project was carried out in close cooperation with DSN Connecting Knowledge, to whom we would like to express our sincere thanks once again.

#ecoship60 #cimnetwork #methanol #hydrogen

For the right solution, please feel free to contact us.

SCHIFFSDIESELTECHNIK KIEL GmbH

Kieler street 177

24768 Rendsburg

Phone: 04331 4471-0

E-Mail: info(at)sdt-kiel.de

01.09.2021 THUS, WE CONTINUE TO PURSUE OUR PERSONNEL DEVELOPMENT AND FILL OUR RANKS THROUGH OUR OWN PERFORMANCE.

SDT DEFIES THE SHORTAGE OF SKILLED WORKERS!

We are pleased that since August we have again two new apprentices industrial mechanics with specialization in mechanical and plant engineering in our team. Thus, we continue to pursue our personnel development and fill our ranks through our own performance.

If you would also like to learn more about training at SDT:

"CAMPFIRE" IS ONE OF THE IMPLEMENTATION PROJECTS OF THE LEAD PROJECT "TRANSHYDE" FOR THE DEVELOPMENT OF A HYDROGEN TRANSPORT INFRASTRUCTURE, WHICH IS ONE OF THREE LEAD PROJECTS OF THE FEDERAL MINISTRY OF EDUCATION AND RESEARCH (BMBF) FOR THE IMPLEMENTATION OF THE NATIONAL HYDROGEN STRATEGY.

SDT IS INVOLVED AS A PARTNER IN THE "CAMPFIRE" IMPLEMENTATION PROJECT.

SDT is committed to green and CO2 reduced energy generation on ships as a partner of the implementation project “Campfire- Wind and Water to Ammonia – Maritime Fuel and Energy Storage for an Emission Free Future”.

www.wir-campfire.de

www.wasserstoff-leitprojekte.de

The objectives of this project include:

– the use of ammonia as an alternative fuel in shipping is one of the keys to reducing CO² emissions

– SDT has been pursuing the development of alternative and environmentally friendly propulsion and power generation solutions for ships in this and other R&D projects, such as “EcoShip60” for several years now

The protection and preservation of our environment is the task for the 21st century.

As SDT we face up to our responsibility.

Take advantage of the existing technical possibilities to operate your combustion engine as environmentally friendly as possible.

Please contact us for the suitable solution.

SCHIFFSDIESELTECHNIK KIEL GmbH

Kieler Straße 177

24768 Rendsburg

Phone: 04331 4471-0

E-Mail: info@sdt-kiel.de

THE SEA AIR MASSIVELY COUNTERACTS THE STANDING TIME AT SEA.

WHAT DO YOU HAVE TO PAY ATTENTION TO IN ANY CASE FOR YOUR EXISTING INSTALLATIONS AT SEA?

As you can see in this picture, we have made this generator fit for use at sea with a special, adapted filter that we have retrofitted.

This is how we optimize your diesel generator according to your needs.

With SDT you have a reliable and pro-active partner who always guarantees you the right quality in service and spare parts supply.

So that you can approach the next maintenance with a strong partner and always be optimally supplied.

Our experienced employees are at your side.

Phone: 04331 4471-0

E-Mail: info@sdt-kiel.de

Service-Hotline:

+ 49 151-120 103 91

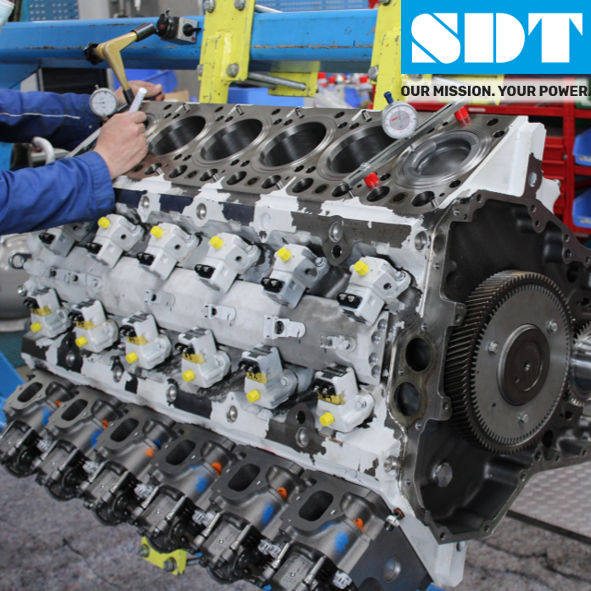

WE ENSURE RELIABLE IMMEDIATE REPAIR OF MARINE ENGINES IN THE SHIP. AT OUR PLANT IN RENDSBURG, WE CAN REPAIR MORE COMPLEX DAMAGE TO ENGINES IN A TARGETED MANNER.

DAMAGE TO THE CONNECTING ROD, OR SEAWATER CONTAMINATION OF THE DRIVE?

Our manufacturer-trained staff will reliably repair your engine so that it can once again meet all requirements at sea and/or in the field.

If you are also looking for a service for your engine, we look forward to hearing from you.

https://www.sdt-kiel.de/en/sdt-service/

E-Mail: info(at)sdt-kiel.de

Service hotline:

+ 49 151-120 103 91

OUR TRAINED MTU AND ZF SERVICE TECHNICIANS ARE DISPATCHED QUICKLY AND EASILY BY AIR OR FERRY. WE HAVE STATIONED COMMON SPECIAL TOOLS AT OUR LOCAL BASE.

WE ALSO MANNED OUR SERVICE BASE ON HELGOLAND WITHIN A FEW HOURS IF NECESSARY.

+ MTU Engines and Systems Service for Propulsion Systems

+ Cross-brand service for offshore diesel generators by trained mechanics

(GWO & DGUV HUET/Sea Survival/ Working at hights etc.)

+ ZF Marine Service

Wherever you are, we come and provide the service. So that you are ready for operation again when needed.

Tel.: 04331 4471-0

Cel: + 49 151-120 103 91

info@sdt-kiel.de

SCHIFFSDIESELTECHNIK KIEL GMBH (SDT) WILL COUNT ON THE KNOW-HOW OF NORIS AND THEREFORE STRENGTHENS THE FOCUS ON INCREASINGLY INDIVIDUAL REQUIREMENTS IN THE AUTOMATION TECHNOLOGY AROUND AGGREGATES IN ITS PROJECT BUSINESS.

SDT DEVELOPS UNIQUE SOLUTIONS FOR PROPULSION AND ENERGY MANAGEMENT WITH NORIS

As an expert for customer-specific solutions, NORIS will support SDT in the design and production of certain types of “Local Operation Panels” (LOPs) for stationary control and monitoring. The automation solution “myNORIS”, which offers maximum flexibility for these applications will be used as the basis.

SDT develops unique solutions for propulsion and energy management for its customers in the maritime sector. One key component is the control and safety equipment of gensets, which are always designed project-specifically. According to Fin-Olav Wittstock, Managing Director of SDT, the requirements here are becoming more and more complex, which is why SDT Kiel has decided to rely on the expertise of NORIS.

We are looking forward to some exciting projects!

Tel.: 04331 4471-0

Cel: + 49 151-120 103 91

info@sdt-kiel.de

IN NOVEMBER 2020 WE HANDED OVER 30 MOBILE EMERGENCY POWER SUPPLY UNITS TO THE STATE OF SCHLESWIG-HOLSTEIN.

HOW DOES SDT IN SCHLESWIG-HOLSTEIN ENSURE THE GENERAL POWER SUPPLY IN CASE OF A NATIONWIDE POWER FAILURE?

In November 2020 we handed over 30 mobile emergency power supply units to the state of Schleswig-Holstein. The Ministry of the Interior made this investment in order to be able to compensate for a nationwide power failure.

The mobile 100kVA power generator has

– 4 cylinder IVECO engine

– Sound enclosure

– FIRECO lighting column

– max. mounting height 9 m

– 6 separate lighting elements 180,000 lumen

– Tandem axle trailer

– Tool cabinet

– 2.9 t total weight

The trailers will be used in the 15 counties and independent cities of Schleswig-Holstein. In the event of a power failure, the system can either be used to feed into the grid at a predefined point, in this case a filling station, or in island operation for conventional consumers.

We would like to take this opportunity to thank those responsible and all suppliers for the great cooperation.

Article in the Schleswig-Holstein Magazine:

https://www.ndr.de/nachrichten/schleswig-holstein/Bernd-Schwiderski,schwiderski100.html

If you also want to secure your power supply in case of a failure, please contact us.

Phone: 04331 4471-0

Mobile: + 49 151-120 103 91

info@sdt-kiel.de

25TH OF MARCH 2020

GENERAL INFORMATION FOR OUR CUSTOMERS AND PARTNERS

Dear customers and partners, 25.03.2020

The situation created by the spread of the coronavirus (COVID-19) leads us to take profound and appropriate measures to ensure the protection of the health of our employees and all business partners with whom we have contact. In view of these circumstances, we have imposed a number of internal restrictions and procedures with regard to recommendations published by the Robert Koch Institute, for example, which we would like to briefly inform you about below:

A working group has been set up to monitor the activities related to COVID-19 according to the instructions of the Federal Government and other authorities, to continuously monitor the situation and to ensure that all SDT employees are kept informed at all times.

Instructions for the right behavior and habits have been posted in all areas of the company for the benefit and safety of all. Hygiene measures were taken and hand disinfection dispensers were installed.

Business trips of any kind were reduced to an absolute minimum or postponed to a future date.

External visits to SDT have been reduced to the absolute minimum. A detailed self-declaration is required for access to our facilities and premises. Meetings with customers/suppliers are only held when absolutely necessary to ensure that our work runs smoothly.

Appropriate measures have been taken to limit the timely presence of employees in the common areas. In addition to the use of home office workplaces, we have set up individual offices for each office staff member.

Our employees are requested to avoid mass events and to respect the rules of social distance in public areas.

All employees have been advised not to come to work if they should have corresponding symptoms such as coughing and/or a cold and/or fever.

We have therefore taken some measures to slow down the spread of the virus. Please support us in this and make equivalent provisions for yourself and your team. We will continue to monitor the situation closely and make every effort to protect the safety of our employees and ensure the smooth running of our activities in the service of our customers.

If you have any questions and as a contact person in our company, Ms Petra Schubert ( schubert@sdt-kiel.de ) will be happy to help you.

With kind regards

SCHIFFSDIESELTECHNIK KIEL GMBH

Thomas Schwarke

CAREER IN SCHLESWIG-HOLSTEIN

With a lot of motivation, within 10 years from a school internship in 2008 to a 3.5 year apprenticeship as an industrial mechanic in the production of energy generation systems. This was followed by a Bachelor of Engineering in Mechanical Engineering as part of an industrial course (IBS). A year as a project planner with a bachelor’s degree added further skills and knowledge. Now he is studying for a Master’s degree, and his motivation is still strong.

CONGRATULATIONS ON PASSING THE SKILLED LABOUR EXAMINATION

We would like to congratulate all newly qualified industrial mechanics, mechatronics technicians and electricians for industrial engineering on passing their final exams. If you are still looking for a great field of work, then we look forward to receiving your application. Please send your documents either by post to the attention of Mr Schwarke ( or by e-mail schwarke@sdt-kiel.de )

SERIAL DELIVERY

Another power generator with the highest standards in terms of sound optimisation and performance leaves our production facility. Size is not everything, but the demand we place on ourselves to fully fulfil customer requirements

5TH OF SEPTEMBER 2018

SDT RECEIVES ORDER FOR THE CONSTRUCTION OF 4 ON-BOARD UNITS

SDT receives the order to build 4 on-board units. The highest demands are placed on structure-borne sound insulation and airborne sound attenuation. SDT uses its modular premium acoustic enclosure system and double elastic bearings.

10TH OF NOVEMBER 2018

SPECIAL COOLING NECESSARY

SDT configured a special type of 2-stage radiator to deliver approx. 2900 kW of heat in particularly difficult ambient conditions. After successful testing on the factory premises, the system was delivered to the customer and put into operation. The entire system is IP69K protected, seawater resistant and classified